Bharat Stage Emission Norms Explained: BS1 to BS6, What Changed & What BS7 Means

- 1Each Bharat Stage norm reshaped how India builds, fuels, and drives its cars.

- 2BS7 will go beyond tailpipes, targeting brake dust, tyres, and even EV batteries.

- 3The diesel era is fading fast as BS7 tightens limits and drives up costs.

- What are Bharat Stage (BS) norms, and Why Do they exist

- The Origin of BS Norms, and Quick Overview on the Journey to BS6

- The Evolution of Bharat Stage Norms: BS-I to BS-VI

- How are the BS Emission Laws Enforced and Tested?

- How the Vehicles Evolved With the Latest Bharat Stage Norms?

- BS7: What’s being discussed & likely direction

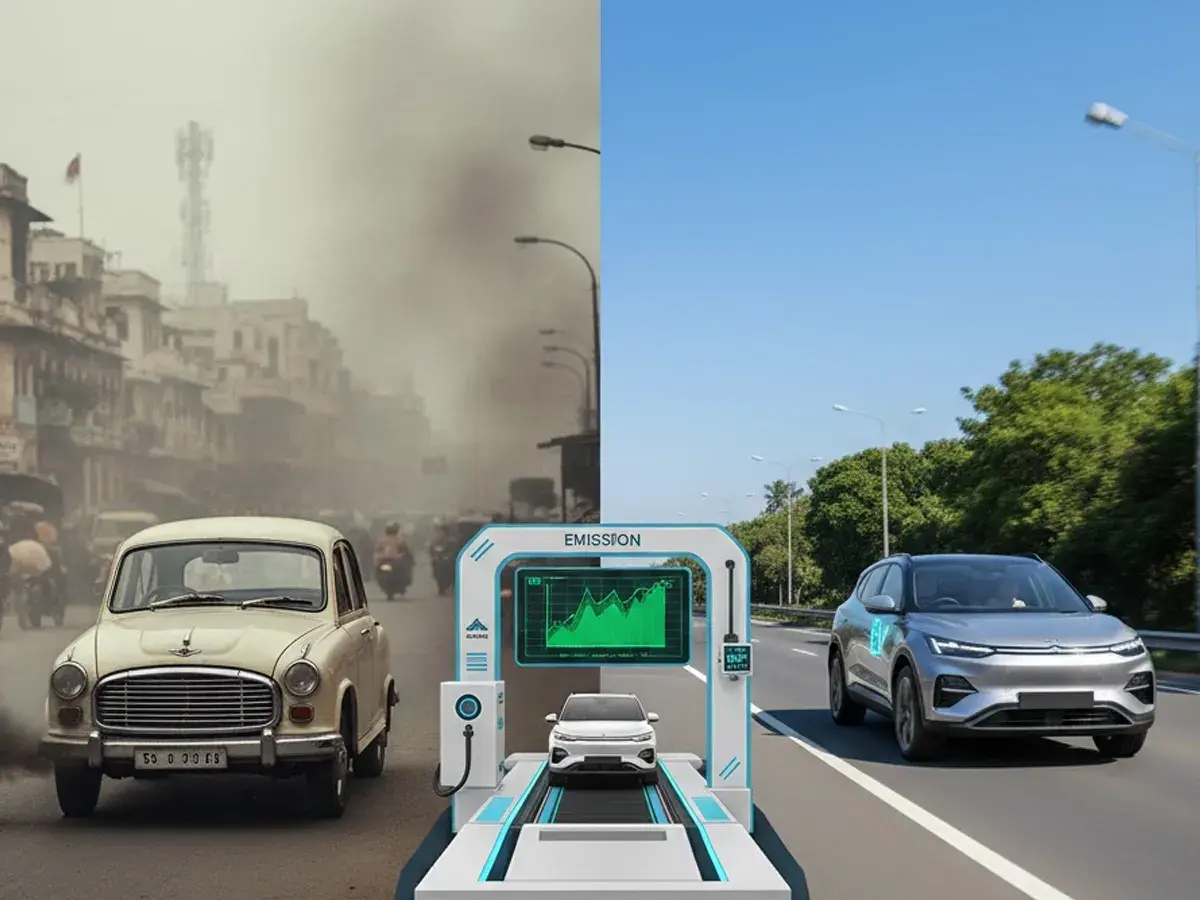

The journey of Bharat Stage (BS) emission norms is definitely more than a tale of regulations. Those blue fumes from 2-stroke engines? Gone. The humble Maruti 800 that once ruled every street? A casualty of progress.

Vehicular pollution is truly a significant contributor to air pollution, choking nearly a third of India’s air. Curbing this very problem serves as the underlying incentive behind the roll-out of increasingly stringent emission norms. However, these norms also soon became a catalyst for innovation. Every new stage tightened the noose, forcing the industry to evolve or fall behind.

Automakers were compelled to rethink powertrains, integrating technologies like electronic fuel injection, advanced catalytic converters, and complex exhaust treatment systems. Meanwhile, oil companies had to keep pace, refining and supplying ultra-low-sulphur fuels to match these new-age engines.

Let’s uncover each phase of the Bharat Stage (BS) emission norms, their evolution from phase 1 to the current phase 6, as well as what the future outlook seems like with the upcoming BS7.

What are Bharat Stage (BS) norms, and Why Do they exist

Overview

At their core, Bharat Stage (BS) emission norms are India’s hardline rulebook for what your vehicle is allowed to breathe out. These norms are government-mandated standards that limit the amount of pollutants vehicles can release into the air.

These norms push vehicle manufacturers to design and integrate new hardware intended to make vehicles more environmentally efficient, such as advanced catalytic converters and exhaust after-treatment systems (e.g., Diesel Particulate Filters and Selective Catalytic Reduction).

What do BS Emission Standards Try to Limit?

The primary purpose of these norms is to improve national air quality and protect public health. This is achieved by mandating progressively stringent limits on the emission of key air pollutants, chiefly Carbon Monoxide (CO), Hydrocarbons (HC), Nitrogen Oxides (NOx), Sulphur Oxides (SOx), and Particulate Matter (PM).

Who sets these standards?

The standards and their implementation timelines are set by the Central Pollution Control Board (CPCB) under the Ministry of Environment, Forest, and Climate Change.

The BS standards are not developed in isolation, as they are modeled directly on the European "Euro" emission standards, providing a well-understood, technology-forcing roadmap, aligning India's regulatory framework with international best practices.

The Origin of BS Norms, and Quick Overview on the Journey to BS6

India’s battle against vehicular pollution officially took shape in the early 1990s. Back then, the basic smoke laws and rudimentary checks did exist to keep emissions under control; however, the real structure arrived in 2000 with the introduction of the first Bharat Stage norm, BS-I, formally known as India 2000.

Modeled after Europe’s Euro 1 standards, it marked a turning point for the Indian auto industry. The move came on the back of a 1999 Supreme Court directive that made it mandatory for all new vehicles to meet these standards by June 2000.

Things truly picked up pace after the Mashelkar Committee report in 2002. It proposed a clear, phased roadmap for emission control, first targeting major metros, then gradually expanding across the country. This plan shaped the National Auto Fuel Policy of 2003, which laid the foundation for BS-II and BS-III rollout.

A decade later, the Auto Fuel Vision and Policy 2025 pushed the agenda further, mapping out the path to BS-IV, BS-V, and eventually BS-VI. The government, however, decided to take a bold leap by skipping BS-V altogether and moving straight from BS-IV to BS-VI. It was an aggressive move that brought India’s emission standards up to par with global benchmarks, years ahead of schedule.

The Phased Implementation of Earlier Bharat Stage Norms

India’s early approach to emission standards followed a pattern that invited both progress and criticism. Instead of uniform nationwide enforcement, Bharat Stage norms were introduced in waves. Take BS-IV, for instance: it came into force in just 13 major cities in April 2010, while the rest of India continued selling BS-III vehicles for another seven years. It wasn’t until April 2017 that BS-IV became a countrywide mandate.

This uneven approach effectively split the market into two realities, while one moved toward cleaner technology, another lagged behind. This actually resulted in the intended air quality gains being diluted, especially as vehicle sales surged in regions operating under laxer norms.

The worsening public health implications left policymakers with little room for half-measures. So, when it came to BS-VI, the government drew a hard line, as April 1, 2020, marked the transition to “one nation, one norm”.

The table below highlights this journey from Bharat 2000 to BS-VI:

| Standard | Euro Equivalent | Date (Introduction) | Region | Key Details |

| India 2000 (BS-I) | Euro 1 | 2000 | Nationwide | First formal emission standard; made catalytic converters mandatory |

| Bharat Stage II | Euro 2 | 2001 (April) | Metro cities like NCR, Mumbai, Kolkata, Chennai | Introduced Multi-Point Fuel Injection (MPFI) as a mandatory requirement |

| 2003 (April) | Major Cities | |||

| 2005 (April) | Nationwide | |||

| Bharat Stage III | Euro 3 | 2005 (April) | 13 Metros and Major Cities | Further tightening of emission standards; shift to improved combustion control |

| 2010 (April) | Nationwide | |||

| Bharat Stage IV | Euro 4 | 2010 (April) | 13 Metros and Major Cities | Primary focus on reducing NOx and PM; electronic control advancements; 7-year gap from BS III |

| 2017 (April) | Nationwide | |||

| Bharat Stage V | Euro 5 | - | Skipped by Policy | The government decided to bypass BS5 to accelerate pollution reduction; the move was controversial but justified by urgency |

| Bharat Stage VI | Euro 6 | 2020 (April 1) check details | Nationwide | Skipped BS5 entirely; represents the most stringent standards globally at the time of implementation; Phase 2 (RDE) implemented April 1, 2023 |

The Evolution of Bharat Stage Norms: BS-I to BS-VI

The quantitative impact of these norms is best understood by examining the allowed emission limits in grams per kilometer (g/km). The following table demonstrates the progressive tightening of these limits for the most critical pollutants.

| Standard | Fuel Type | CO (g/km) | HC+NOx (g/km) | NOx (g/km) | PM (g/km) |

| BS-II | Petrol | 2.72 | 0.97 | - | - |

| Diesel | 1.00 | 0.70 | - | 0.08 | |

| BS-III | Petrol | 2.30 | - | 0.15 | - |

| Diesel | 0.64 | 0.56 | 0.50 | 0.05 | |

| BS-IV | Petrol | 1.00 | - | 0.08 | - |

| Diesel | 0.50 | 0.30 | 0.25 | 0.025 | |

| BS-VI | Petrol | 1.00 | - | 0.06 | 0.0045* |

| Diesel | 0.50 | 0.17 | 0.08 | 0.0045 |

India 2000 (BS-I)

The story began in April 2000 with Bharat Stage I, officially known as India 2000. This was India’s first real attempt at controlling vehicle emissions. Modeled after Europe’s Euro 1 standards, it introduced tailpipe limits for CO, HC, and NOx in passenger and light commercial vehicles. Petrol engines now required catalytic converters, while diesel vehicles faced simpler caps. This phase also marked a major transition in the quality of fuel, as leaded petrol was permanently banned, and unleaded fuel became the new nationwide standard

BS-II

The next upgrade, Bharat Stage II, arrived with tougher limits on CO, HC, and NOx, along with a new 500 ppm sulfur ceiling for both petrol and diesel. Rolled out in metros around 2001 and extended across India by April 2005, BS-II forced manufacturers to modernize. Petrol cars moved away from carburetors, adopting electronic multi-point fuel injection systems, while catalytic converters and engine control systems became far more advanced.

BS-III

Bharat Stage III pushed the boundaries further. It slashed permissible levels of NOx, HC, and particulate matter (PM), with nationwide enforcement starting in April 2010. This phase introduced basic On-Board Diagnostics (OBD-I) that allowed real-time monitoring of emission performance. To comply, automakers fine-tuned engine calibration and optimized exhaust catalysts, supported by cleaner fuels with reduced sulfur content.

BS-IV

Bharat Stage IV was a serious tightening of the screws. With roughly half the NOx and PM limits of BS-III, it demanded much cleaner combustion. A 50 ppm sulfur cap was imposed on fuels, and modern technologies like common-rail direct injection became industry norms. OBD Phase II systems followed in 2013. Though phased across cities between 2010 and 2016, BS-IV finally became a nationwide mandate in April 2017.

BS-VI

India skipped BS-V entirely and jumped straight to Bharat Stage VI, which was implemented nationwide in April 2020. The move set a global benchmark, cutting sulfur levels to an ultra-low 10 ppm and enforcing the use of advanced emission control systems. Diesel vehicles now required particulate filters (DPF) and selective catalytic reduction (SCR) units to meet the new standards.

The evolution continued with BS-VI Phase 2, introduced on April 1, 2023, adding advanced on-board diagnostics and Real Driving Emission (RDE) tests.

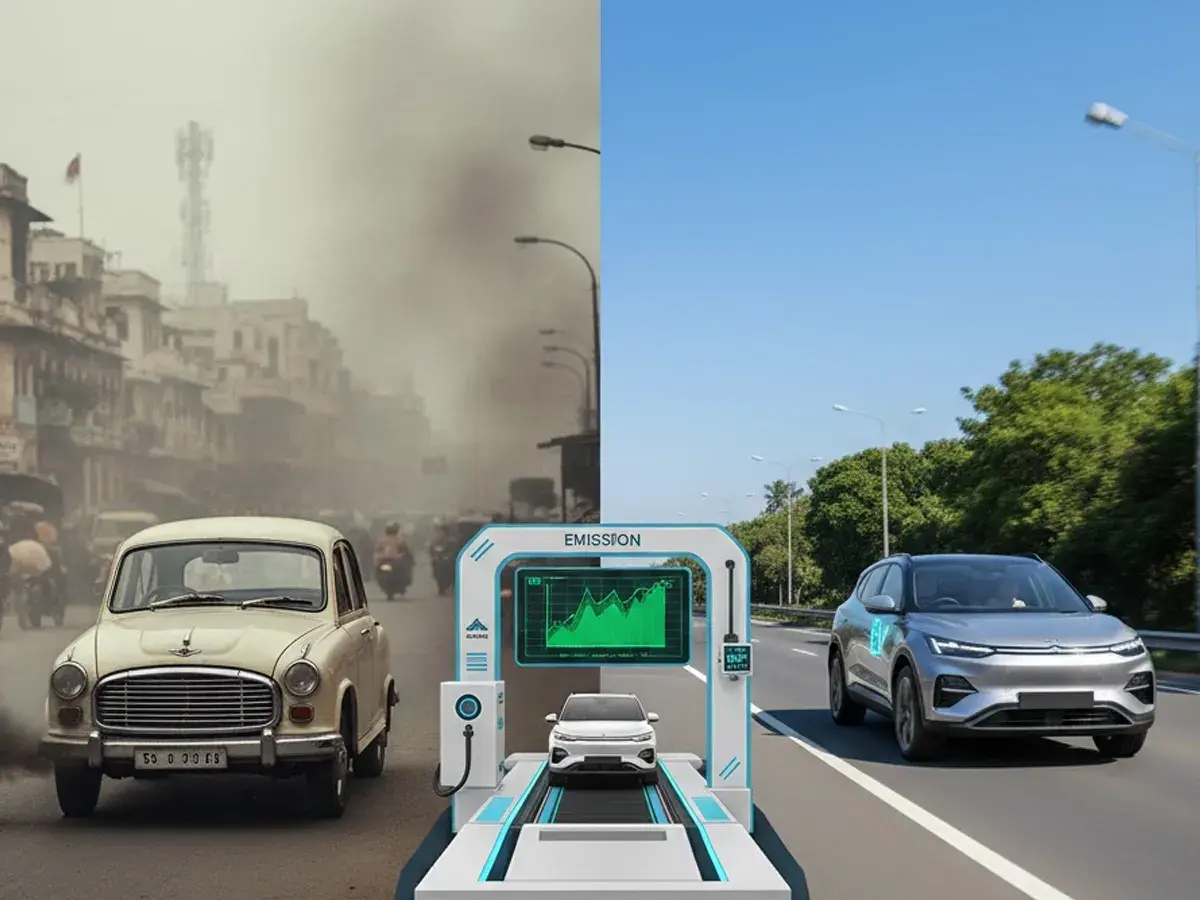

How are the BS Emission Laws Enforced and Tested?

Behind every Bharat Stage regulation lies an intricate web of checks, balances, and testing protocols designed to keep automakers accountable. The system rests on three core pillars:

- Central Pollution Control Board (CPCB): The apex authority that sets the emission benchmarks and rollout timelines.

- Ministry of Road Transport & Highways (MoRTH): The ministry that gives these standards legal shape by notifying them under the Central Motor Vehicles Rules (CMVR).

- Test Agencies: Institutions like the Automotive Research Association of India (ARAI) and other accredited labs are tasked with certification. They also define the detailed testing methods, for instance, Automotive Industry Standard (AIS) 137, which governs Real Driving Emission (RDE) tests.

Enforcement itself follows a tightly controlled three-step cycle that begins at the factory and extends to vehicles already in use:

1. Type Approval (TA)

Before a new model ever reaches the market, a pre-production vehicle undergoes extensive lab testing at agencies such as ARAI. These tests simulate real driving conditions, including RDE cycles for BS-VI models, to confirm that the design meets emission limits. Only after clearing these trials does the model receive approval for sale.

2. Conformity of Production (COP)

Once the vehicle is in mass production, random units are pulled straight off the assembly line and re-tested. This ensures that the vehicles being sold are true to the certified prototype and not cutting corners in manufacturing or calibration.

3. In-Service Conformity (ISC)

Compliance doesn’t end once the vehicle hits the road. Under ISC, regulators can test vehicles already in use, often using Portable Emission Measurement Systems (PEMS), to verify that real-world emissions still stay within the prescribed limits. If a model fails to comply, manufacturers can face penalties, recalls, or both.

Together, these layers form a tightly sealed regulatory loop. Combined with the vehicle’s onboard diagnostics (OBD) system, they create what’s essentially a “no-exit” framework.

How the Vehicles Evolved With the Latest Bharat Stage Norms?

The leap to Bharat Stage VI wasn’t a case of fine-tuning engines or tweaking emission maps, but a complete mechanical and chemical overhaul.

Fuel upgrades

One of the biggest transformations under BS6 started right at the pump. The sulphur content in fuel was slashed from 50 ppm in BS4 to just 10 ppm. That’s an 80% cut in one stroke. This was essential because sulphur is the silent killer of emission systems. It forms sulfur dioxide and sulfates, which are compounds that pollute the air and directly harm your lungs.

More critically, sulphur poisons the very filters and catalysts that clean modern exhaust gases. It clogs Diesel Particulate Filters (DPF) and damages the Selective Catalytic Reduction (SCR) units that BS6 diesel engines rely on.

Since BS4 fuel depended on natural sulphur for lubrication, refiners had to introduce advanced additives to replicate that effect. Diesel also got cleaner with a reduction in poly-aromatic hydrocarbons (PAH) from 11% to 8%, cutting down on cancer-causing emissions.

Diesel Tech

Diesel Particulate Filter (DPF):

Think of the DPF as a fine-mesh trap sitting in the exhaust path, catching microscopic soot before it escapes into the air. Built as a ceramic honeycomb, this filter captures particulate matter so effectively that tailpipes no longer belch the thick, black smoke once common in older diesels.

However, over time, soot accumulates inside the filter, restricting flow. To clear it, the DPF uses a process called regeneration, where trapped soot is burned off and turned into carbon dioxide and water. This alone cuts particulate emissions by nearly 90% compared to BS4 diesels.

Regeneration happens in two ways:

- Passive regeneration activates automatically at highway speeds when the exhaust gets hot enough.

- Active (or forced) regeneration kicks in when passive cleaning isn’t possible, which is usually the case in stop-go city traffic. Here, the ECU injects extra fuel into the exhaust stream, creating heat to burn the soot away.

.

Selective Catalytic Reduction (SCR):

The biggest leap for BS6 diesels came from Selective Catalytic Reduction, the system that changed how engines tackle nitrogen oxides (NOx). SCR injects a urea-water mix, commonly known as AdBlue or Diesel Exhaust Fluid (DEF), into the exhaust before it reaches the catalyst. Under heat, urea breaks down to form ammonia, which reacts with NOx to produce harmless nitrogen and water vapor.

It’s clever chemistry, but it comes with upkeep. The AdBlue tank needs periodic refilling, typically every few thousand kilometers, depending on vehicle size and usage. Consumption for most passenger diesels ranges between 5 to 20 liters, and modern vehicles display fluid levels on the instrument cluster.

Lean NOx Trap (LNT)

For smaller or budget-friendly diesel models, the Lean NOx Trap is a simpler setup. It captures NOx during lean-burn phases and purges it when the engine briefly runs rich. LNT is cheaper and easier to package than SCR, but less efficient under heavy loads or on larger engines. Automakers like Tata Motors have adopted this setup for compact diesels where cost and space outweigh performance trade-offs.

On-Board Diagnostics (OBD) & Real Driving Emissions (RDE)

The second phase of BS6, rolled out on April 1, 2023, marked a turning point in how India measures and enforces emissions compliance. The focus moved beyond the test lab to the real world.

Now, every vehicle must prove its cleanliness not only under controlled laboratory cycles but also in live driving conditions through Real Driving Emissions (RDE) tests. In other words, it’s no longer enough for a car to behave well on a dyno; it has to stay clean in traffic, on inclines, in heat, and through unpredictable throttle patterns.

For certification, vehicles are fitted with a Portable Emissions Measurement System (PEMS) that records emissions as the car drives through real roads, simulating everyday conditions.

At the same time, upgraded On-Board Diagnostics (OBD) systems continuously monitor the health of emission control components throughout the vehicle’s life. Any malfunction triggers alerts through the dashboard.

BS7: What’s being discussed & likely direction

With BS6 Phase 2 now in full effect, the spotlight has shifted to the next big leap, which is Bharat Stage 7 (BS7). This time, though, the tone from policymakers is clear: India doesn’t want another last-minute sprint like the jump from BS4 to BS6.

Government Posture: The Proactive Push

Unlike the chaotic, reactive leap to BS-VI, the government is signaling its intent for BS-VII proactively. Union Transport Minister Nitin Gadkari has already urged automakers to start preparing for BS7, signaling a far more proactive posture.

An official timeline is yet to be announced, but history offers a clue. India typically trails Europe’s emission roadmap by a few years. With Euro 7 regulations expected to take effect soon, India’s BS7 standards will likely surface between 2027 and 2028.

What Euro 7 / BS7 Conversations are Focusing On

Bharat Stage VII will closely follow the upcoming Euro 7 norms, and that’s where things get interesting. Unlike earlier emission updates that focused mainly on tailpipes, this one widens the lens to the entire environmental footprint of a vehicle.

One Standard for All Fuels

BS7 is expected to introduce a level playing field for petrol and diesel emissions. If implemented as proposed, diesel cars would need to meet the same nitrogen oxide (NOx) limits as petrol ones, which is 60 mg/km. For context, that’s a steep drop from the current 80 mg/km, and it’ll push diesel engines into far more complex (and costly) engineering territory.

Limit on Non-Exhaust Emissions

For the first time, the regulations will step beyond engine emissions. The focus now includes pollutants that come from using the car.

- Brake Dust: Fine particulate matter produced as pads and rotors wear down.

- Tire Abrasion: Microplastic particles released as tires rub against the road.

These sources, long overlooked, are now acknowledged as major contributors to urban air pollution. Automakers will have to rethink materials and compounds, from low-wear brake formulations to cleaner tire rubber blends, to cut down microparticle emissions.

On-Board Monitoring (OBM)

BS7 will also bring a powerful new layer of oversight in the form of the On-Board Monitoring (OBM) system. Unlike the current OBD systems that check for faults, OBM goes several steps further. It tracks NOx, ammonia, and particulate emissions in real time, storing data accessible to manufacturers, regulators, and service centers. In essence, your car will carry its own compliance auditor, ensuring it stays clean throughout its life, not just during lab tests.

The EV Angle: Battery Rules Take Shape

For electric and plug-in hybrid vehicles, BS7 will add accountability to battery performance. Regulators plan to measure battery health and charge retention over time and distance, ensuring that cells maintain longevity. It’s a step meant to build trust in EVs while reducing the risk of battery waste down the line.

What It Means for You?

1. Higher Vehicle Costs:

Cars will get pricier. OBM systems, re-engineered brake and tire materials, and stricter powertrain controls all add up to the sticker price.

2. The Decline of Diesel for the Masses:

Affordable diesel cars are nearing their end. The cost of engineering a diesel engine to meet 60 mg/km NOx limits will simply be too high for most passenger vehicles, restricting diesel to heavy-duty or premium segments.

3. Stronger EV Confidence:

On the positive side, mandatory EV battery durability checks could serve as a built-in guarantee. Knowing your EV’s battery is tested for longevity will boost buyer confidence and strengthen the used-EV market.

4. Faster Depreciation for Older Cars:

The rollout of BS7 will likely make older BS3 and BS4 vehicles lose value faster, as buyers shift toward compliant, lower-emission alternatives.

Frequently Asked Questions

Expand all